The rubber production sector can be a dynamic landscape, continually evolving to fulfill the demands of diverse sectors like automotive, building, and purchaser merchandise. As organizations attempt for higher efficiency, lessened squander, and Improved product quality, the need for State-of-the-art rubber reducing solutions has never been much more essential. In 2025, the rubber reducing device marketplace is about to witness groundbreaking innovations that could redefine precision and efficiency. Whether you happen to be producing intricate automotive seals, sturdy industrial conveyor belts, or custom made-created rubber parts, buying a point out-of-the-art reducing machine is not just a possibility—it is a strategic crucial. This article meticulously analyzes the highest 5 rubber reducing equipment poised to dominate the market in 2025, starting from fully automatic CNC devices to higher-worth, consumer-welcoming types. Prepare to discover the automatic rubber cutting machine manufacturers best Alternative to improve your production processes and get a competitive edge. If your company is looking for a cnc leather cutting machine company, You then've arrive at the best area. Let's dive in!

Table of contents:

LatheGlobal SK1600: The Fully automatic CNC Revolution

NauticExpo Mecanumeric: Rugged trustworthiness for Harsh Environments

DirectIndustry OP srl: High-pace Rotary reducing for Mass manufacturing

Barwell Strip Cutter: Versatility and economic system in Strip chopping

REMA-TIPTOP product 32: Portability and Affordability for Smaller Operations

LatheGlobal SK1600: The Fully Automated CNC Revolution

https://latheglobal.com/products/cnc-cutting%EF%BC%8Crubber-cutting-machine-with-fully-automatic-felt-leather-cutting-sk1600

model Overview: LatheGlobal has recognized alone as a leader in CNC cutting engineering, regularly pushing the boundaries of innovation and general performance. Their determination to excellent, precision, and automation has acquired them a loyal customer base across many industries.

critical functions and Benefits:

The LatheGlobal SK1600 is not merely a rubber chopping equipment; It is a comprehensive manufacturing Option. This thoroughly automatic CNC program is created to manage a big selection of supplies, which includes rubber, felt, and leather, making it an unbelievably adaptable asset for organizations with varied product traces. The SK1600 distinguishes by itself by a number of key rewards:

clever CNC method with AI Optimization: At the guts of your SK1600 lies a sophisticated CNC program run by subtle AI algorithms. This method optimizes cutting paths in actual-time, examining content Homes and geometry to minimize squander and maximize performance. end users have documented a discount in substance waste of up to twenty% in comparison with regular reducing procedures. The AI also learns from Just about every slicing operation, consistently refining its algorithms to enhance general performance over time.

Modular design and style for Unparalleled overall flexibility: The SK1600 encompasses a modular structure that permits for quick Resource alterations and customization. This flexibility is essential for firms that tackle elaborate styles and various material thicknesses. The machine could be effortlessly configured with diverse cutting heads, blades, and equipment to support a wide array of slicing responsibilities. The modularity also simplifies upkeep and upgrades, guaranteeing the equipment continues to be up-to-day with the most up-to-date technological enhancements.

Electrical power-successful Procedure: In today's environmentally conscious earth, energy effectiveness is actually a vital element. The SK1600 is engineered to attenuate Vitality usage devoid of compromising performance. in comparison with traditional rubber slicing devices, the SK1600 offers a 35% reduction in Electrical power use. This translates into sizeable Charge financial savings about the equipment's lifespan and contributes to a more sustainable producing Procedure.

Unwavering Precision: Precision is paramount in rubber producing, in which even slight deviations may lead to defects and squandered materials. The SK1600 provides millimeter-degree precision, guaranteeing that each Slice is accurate and reliable. This volume of precision is important for manufacturing high-high-quality factors that fulfill stringent sector standards.

person-welcoming Interface: Regardless of its State-of-the-art capabilities, the SK1600 is developed with person-friendliness in your mind. The intuitive interface can make it quick for operators to system reducing paths, monitor efficiency, and troubleshoot concerns. Comprehensive education and help are provided in order that people can promptly learn the device's functionalities.

automated materials Feeding and Unloading: cut down labor fees and improve throughput While using the SK1600's automated materials managing method. This system can automatically feed and unload supplies, reducing downtime and permitting for steady, unattended Procedure.

suitable Applications:

The LatheGlobal SK1600 is ideally fitted to brands of automotive parts, high-close sealing alternatives, and custom made-built rubber merchandise. Its precision, flexibility, and automation capabilities allow it to be a precious asset for businesses that demand the best levels of high quality and effectiveness. If you are trying to find an automatic rubber chopping equipment maker, LatheGlobal might be your selection.

NauticExpo Mecanumeric: Rugged trustworthiness for Harsh Environments

https://www.nauticexpo.com/prod/mecanumeric/product-64198-561025.html

model Overview: NauticExpo Mecanumeric specializes in offering long lasting and trusted chopping answers for demanding industries, specially the maritime and weighty industrial sectors. Their machines are renowned for his or her potential to withstand harsh conditions and provide regular efficiency.

essential Features and Positive aspects:

The NauticExpo Mecanumeric vibration knife slicing procedure is constructed to endure the rigors of tough industrial environments. This device is engineered by using a concentrate on sturdiness, dependability, and reducing functionality.

Corrosion-Resistant Design: intended especially for humid and corrosive environments, this slicing system features a strong development that resists rust and degradation. All vital parts are addressed with protective coatings to be sure extended-lasting effectiveness, even in one of the most difficult circumstances.

higher-electrical power chopping abilities: This device delivers Remarkable chopping electrical power, very easily handling rubber composite resources up to 50mm in thickness. The higher-torque slicing head ensures thoroughly clean, specific cuts without tearing or deformation.

Real-Time checking procedure: The integrated sensor procedure offers true-time comments on blade have on and general performance, allowing operators to proactively deal with possible troubles prior to they lead to downtime. This predictive maintenance ability will help lessen interruptions and maximize productivity.

consumer-helpful Interface: The intuitive control panel simplifies operation and permits effortless programming of reducing parameters. The procedure also features a library of pre-established chopping profiles for widespread resources, streamlining the setup system.

Robust basic safety options: basic safety is a leading priority in industrial environments. This cutting method is provided with extensive basic safety options, including emergency end buttons, gentle curtains, and interlocking guards, to shield operators and prevent mishaps.

great programs:

This cutting system is correctly suited for the production of maritime seals, rubber factors for port gear, as well as other heavy-duty purposes where longevity and reliability are paramount.

DirectIndustry OP srl: High-Speed Rotary slicing for Mass Production

https://www.directindustry.com/prod/op-srl/product-17876-1076745.html

brand name Overview: OP srl, an Italian company, is identified for its abilities in planning and developing high-velocity chopping machines for mass output applications. Their devices are recognized for their performance, precision, and dependability.

important Features and Rewards:

The DirectIndustry OP srl rotary cutting device is engineered for prime-quantity production, delivering Fantastic velocity and accuracy. This equipment is ideal for producers trying to find To maximise throughput and lessen manufacturing costs.

twin-Axis Synchronization Technology: This device utilizes Sophisticated twin-axis synchronization know-how to obtain a forty% rise in slicing efficiency in comparison with conventional rotary cutters. The synchronized motion on the chopping head and content feed assures sleek, precise cuts at superior speeds.

specific force Manage: retaining consistent strain is critical when cutting dense rubber materials. This machine features a classy strain Handle system that stops deformation and makes sure clean up, sleek cuts every time.

Compact Footprint: Designed for House-constrained environments, this rotary cutter offers a compact footprint that minimizes ground Area prerequisites. This can make it ideal for small and medium-sized factories exactly where House is in a high quality.

constant Web Processing: The device is meant to manage constant rolls of fabric, letting for uninterrupted manufacturing operates. This element is especially effective for makers of conveyor belts and rubber gaskets.

Automated stress Management: The built-in pressure Handle method maintains regular material rigidity all through the chopping system, stopping wrinkles and guaranteeing exact cuts.

Ideal apps:

This rotary cutting device is nicely-fitted to the mass creation of conveyor belts, rubber gaskets, along with other higher-quantity rubber components.

Barwell Strip Cutter: Versatility and financial state in Strip Cutting

https://barwell.com/products/strip-cutter/

model Overview: Barwell, an extended-founded British firm, focuses on delivering flexible and affordable rubber processing alternatives. Their Strip Cutter is noted for its simplicity, reliability, and simplicity of use.

Key capabilities and Rewards:

The Barwell Strip Cutter is a versatile and price-efficient Alternative for slicing rubber strips of different widths. This equipment is perfect for corporations that demand versatility and affordability in their strip reducing operations.

Adjustable Width options: This device permits speedy and straightforward adjustment of strip width from 1mm to 200mm. The adjustable die program simplifies changeovers and minimizes downtime.

lower-upkeep style: The simplified mechanical design and style decreases servicing demands and minimizes the chance of breakdowns. This translates into lower running charges and increased uptime.

silent Procedure: by using a sound level beneath 75dB, this strip cutter makes a far more comfortable and productive Doing the job ecosystem.

basic Procedure: The uncomplicated structure will make the device effortless to work, even for inexperienced users. nominal coaching is necessary to start.

tough building: designed to resist the calls for of industrial environments, this strip cutter encompasses a sturdy design that guarantees extended-lasting functionality.

great programs:

This strip cutter is perfect for the preliminary processing of rubber tubing, sealing strips, and various strip-shaped rubber factors.

REMA-TIPTOP Model 32: Portability and Affordability for Smaller functions

https://www.rema-tiptop.com.au/product/rubber-cutting-machine-model-32/

manufacturer Overview: REMA-TIPTOP is a world leader in furnishing options for conveyor belt routine maintenance and rubber processing. The Model 32 transportable cutting machine is made for affordability, ease of use, and portability.

essential capabilities and Added benefits:

The REMA-TIPTOP product 32 transportable chopping machine is a value-effective and user-pleasant Resolution for modest to medium-sized companies. This device is made for portability, ease of use, and affordability.

a single-Touch Operation: The simplified controls make the machine quick to function, even for inexperienced customers. negligible teaching is required to begin.

light-weight and transportable: The light-weight style permits simple transportation and set up in several places. This makes it perfect for firms that need to have to move the device involving workshops or occupation internet sites.

sturdy Blade: The carbon steel blade is made for extended-Long lasting overall performance, decreasing the necessity for Regular replacements.

Affordable price tag: The Model 32 provides an outstanding price proposition, offering trusted slicing effectiveness at An inexpensive rate point.

security characteristics: The equipment is equipped with safety attributes such as a blade guard and unexpected emergency quit button to guard operators.

best apps:

This transportable reducing device is properly-fitted to repair service outlets, customized fabrication outlets, and modest-batch manufacturing runs.

The rubber chopping technologies landscape in 2025 is characterized by a focus on intelligent automation, Strength performance, and flexible generation abilities. with the entirely automatic CNC innovations of LatheGlobal for the lightweight layout of REMA-TIPTOP, the enhancements in rubber slicing know-how are enabling firms to enhance their generation procedures and obtain new levels of performance and top quality.irrespective of whether you require higher-precision reducing for complicated geometries or cost-helpful remedies for mass production, the devices reviewed in the following paragraphs supply trustworthy and revolutionary selections. when you Examine your reducing requirements and attempt to boost your functions, consider Discovering the State-of-the-art solutions provided by computerized rubber chopping machine producers like LatheGlobal; they can assist you unlock the full prospective of your respective rubber manufacturing procedures.

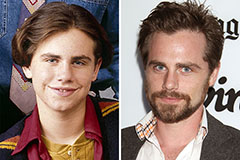

Rider Strong Then & Now!

Rider Strong Then & Now! Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!